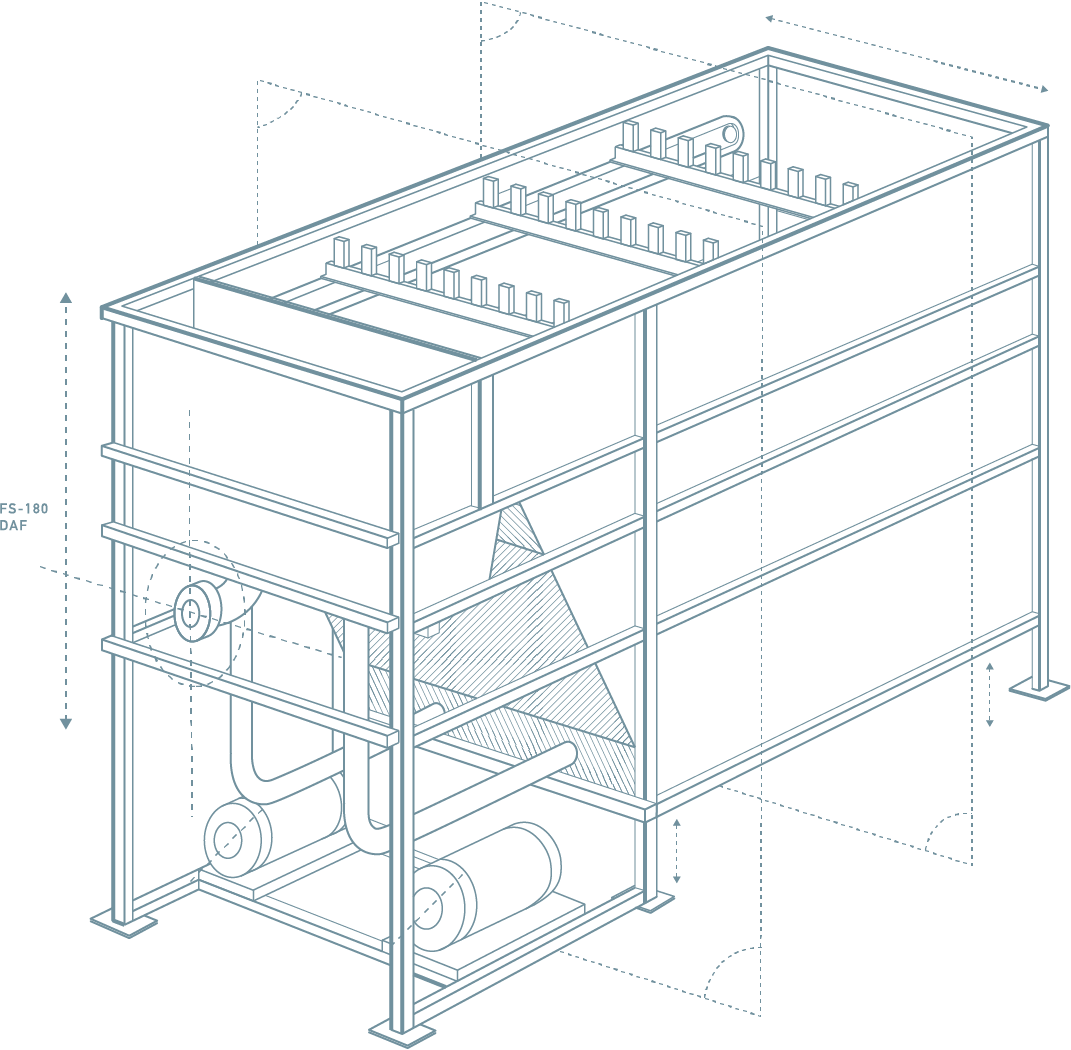

FS-Series DAF Units

Custom-fabricated water and wastewater treatment plants.

Our Dissolved Air Flotation “DAF” units use a pressurized stream of water to deliver dissolved air to an incoming wastewater treatment stream that contains flocculated waste.

When the pressure of the dissolved air and water stream is reduced, the air effervesces out of the water and attaches itself to the waste particles. These particles are then buoyant and will float to the surface. Once at the surface, the particles form a thick sludge blanket which is then drawn to the exit of the DAF unit and scraped into a sludge hopper. The clean, pollutant free water leaves the bottom of the DAF unit.

Features + Benefits

Saturated Air Stream

What separates our DAF units from competitor units are maximized dissolved air to water ratios. Using a specialized high pressure pump, air is sheared and dissolved into the Recycle Air Stream (RAS) water. The air is given time and surface area to fully saturate into the water via our engineered saturator vessels. This means that our DAF systems deliver the physical maximum amount of air that can be dissolved for a given operating pressure which reduces the need for bigger pumps, motors, and complex compressed air systems to deliver sufficient air.

JNE Environmental’s design for DAF Unit sludge handling is superior to our competitors. Other DAF water treatment systems combine sludge skimming and scraping functions into a singular unit. These single drive units do not maximize sludge dryness or save on construction costs. Our DAF units provide a separate sludge thickening skimmer and sludge removal scraper with variable frequency drives, enabling the speed of these two units to be changed independently. This allows for precise fine tuning of the sludge dryness, minimizing sludge removal costs.

Maximized Air to Solids Ratio

JNE Environmental has also maximized the attachment of air bubbles by providing low velocity contact time in the inlet piping and in the first compartment of the DAF Unit. This ensures that all of the available air can attach directly onto a particle (lower Gibb’s free energy) instead of relying on the air bubbles colliding with particles and attaching like many of our competitors designs.

Total Cost of Ownership

The JNE Environmental FS Series DAF Units were designed with our customers total cost of ownership in mind. Some competitor units use systems that vent air continuously to maintain the air-to-water operating level within their contactors. This is wasteful and increases the cost of operation. Our DAF water treatment systems are designed to minimize the cost of compressed air by only consuming as much air as can be dissolved into the water.

Another total cost of ownership benefit of the JNE Environmental FS Series DAF Units is the reduced electricity cost of operating our Recycle Air Stream (RAS) pumps. Our RAS pumps are specifically designed to maintain consistent flow and pressure while maximizing air use. This keeps the overall horsepower of the pump motor smaller than our competitors’ traditional multi-stage centrifugal pumps.

Specifications

| Model | USGPM* | Square Footage | RAS Stream GPM | Air NGPM | Incoming TSS** |

|---|---|---|---|---|---|

| FS-10 | 5-40 | 10 | 2-5.7 | 0.5 | 0–3000 |

| FS-20 | 10-80 | 20 | 2-11.0 | 0.9 | 0–3000 |

| FS-30 | 15-120 | 30 | 2-17.5 | 1.4 | 0–3000 |

| FS-60 | 30-240 | 60 | 10-30.7 | 2.5 | 0–3000 |

| FS-90 | 45-360 | 90 | 10-50 | 4 | 0–3000 |

| FS-120 | 60-480 | 120 | 10-66 | 5 | 0–3000 |

| FS-180 | 90-720 | 180 | 10-100 | 8 | 0–3000 |

| FS-180 | 120-960 | 240 | 10-123 | 10 | 0–3000 |

| FS-180 | 240-1920 | 480 | 20-254 | 15 | 0–3000 |

| FS-180 | 320-2560 | 640 | 40-738 | 60 | 0–3000 |

*USGPM = “Gallons per Minute” based on incoming flow rate. **Incoming TSS Figures = Up to 12,000 mg/L can be designed.

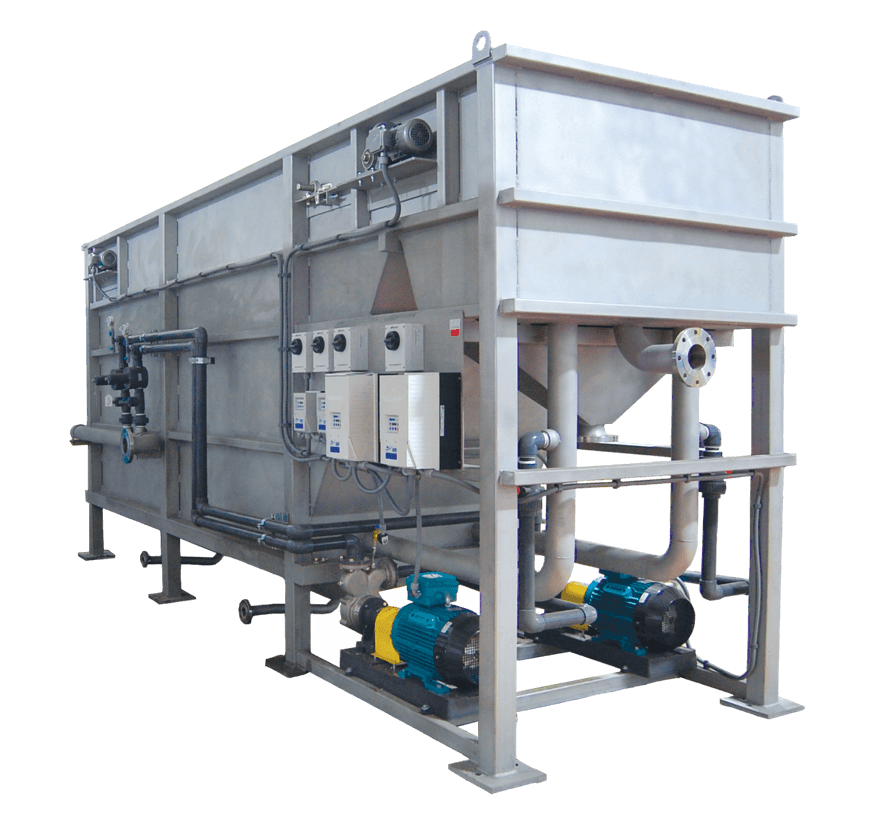

| Construction | Stainless Steel (304) |

| Sludge Hopper Sensors | High and Low With/Without Timer |

| Bottom Hopper Valves | Air Actuated With/Without Timer |

| Sludge Pump | Air-Actuated Diaphragm Pumps available for all models |

| Discharge TSS Probe | High resolution or economical low resolution options available for all models |

| Skimmer Drives | Single or Dual |

| Remote Start | Remote start and speed control can be integrated with automation |

Made in Ontario

Unlike many of our competitors, we manufacture our own equipment locally in Ontario instead of rebranding machinery from overseas. All of our products use locally sourced steel and equipment promoting North American businesses.

Connect

Services + Products

JNE Environmental is a full-service wastewater treatment company. We supply and manufacture our own wastewater treatment systems, equipment, products and services for a wide range of industrial clients. Our solutions include system design, manufacturing, and supply treatment of FOG, TSS, BOD/COD, metals, pH, and more.