Vacuum Degasser —

Sampling System Upgrade

PLC + HMI Design and Commissioning

Legacy Project

A major steel producer in Hamilton, Ontario had a steelmaking improvement program that consisted of more than thirty projects completed over three years between 2005 and 2008. These projects involved both the Basic Oxygen Furnace (BOF) line and the Electric Arc Furnace (EAF) line and ranged in complexity, size, cost, and duration.

The following is a description of the Vacuum Degasser Sampling System Upgrade project.

A ladle is a vessel used in steelmaking processes to transport and pour out molten materials. Once a ladle has been filled with molten steel, it is brought to the Ladle Metallurgical Facility (LMF) so that the steel can be further processed to ensure it meets the quality standards appropriate to the product being produced. In some cases, the ladle is placed in the degas tank. Following the degassing of the steel, a temperature/oxygen reading and a solid sample is taken and sent to the LMF lab for analysis.

Ladle carrying molten steel in steelmaking plant.

Originally, the sampling unit had a dedicated lance for solid sampling and one for temperature/oxygen sampling. If a lance was malfunctioning or damaged, the sample type associated with its corresponding lance could not be taken. Since a temperature/oxygen sample is imperative to ensuring the steel falls into the required parameters, it was not an option to forego taking the sample entirely.

As a workaround, a manual temperature/oxygen lance was in place to allow the operator to open a port and lower the lance manually to obtain this sample. This, however, was a safety concern as it could potentially expose the operator to extreme heat and gases.

The goals of this project were to improve the sample quality as well as the reliability of the sampling system itself.

JNE Automation was brought in to engineer and design the mounting of new, improved sampling units, control system design and integration of the new sampling units into the client’s existing HMI platform, and onsite installation, commissioning, and operator training of the new systems.

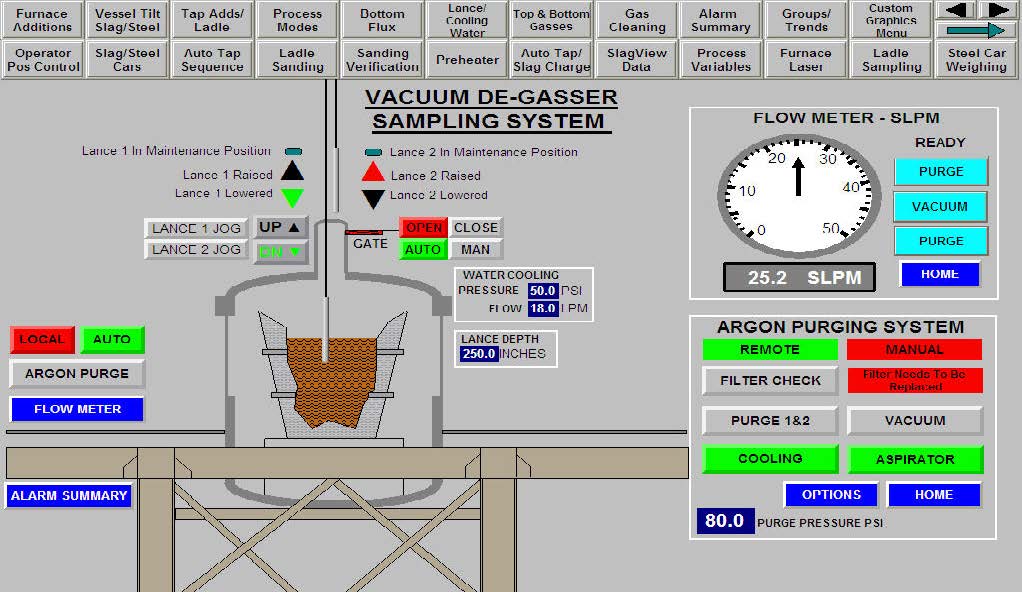

Human Machine Interface (HMI) for the Vacuum Degasser Sampling System.

The upgraded sampling system had dual functionality lances, which allowed for both solid samples and temperature/oxygen samples on either lance. This new, built-in dual functionality increased the reliability of the samplers, and the removal of the manual lance and port improved operator safety.

Argon purging was added for the purpose of solid sampling. This addition ensured that the solid sample taken was void of any inclusions, improving sample quality and enabling better process control.

JNE Automation’s scope of work for this project was as follows:

Do you require assistance with a steelmaking project? JNE can provide the multi-disciplinary services you need, from engineering and design to automation services, installation, commissioning, and training.

With offices in Hamilton, Ontario, Pittsburgh, Pennsylvania, and Detroit, Michigan, and over 40 years of experience in the steel industry, we can serve your engineering needs across the USA and Canada.

Contact Us

Hamilton ON / Pittsburgh PA / Detroit MI

Need assistance with your next project? Our offices are strategically positioned in Canada and the USA to provide the engineering and design services you need.

Connect

JNE Automation’s control systems engineers specialize in continuous process and safety control systems, modernizing PLC and HMI systems, integrating OEM equipment, and supplying custom control panels. Based in Hamilton, Ontario, Canada, we service clients locally, nationally, and internationally.